Cold Chain Military: How Temperature-Sensitive Medicines Stay Safe in the Field

When you think of cold chain military, a system designed to maintain precise temperature control for pharmaceuticals during transport and storage in military operations. Also known as temperature-controlled logistics for defense medicine, it’s not just about keeping drugs cold—it’s about keeping soldiers alive. A single dose of a vaccine or antibiotic can lose its effectiveness if it gets too hot or too cold, even for a few hours. In a combat zone, a broken cold chain doesn’t just mean a wasted shipment—it means troops go without treatment when they need it most.

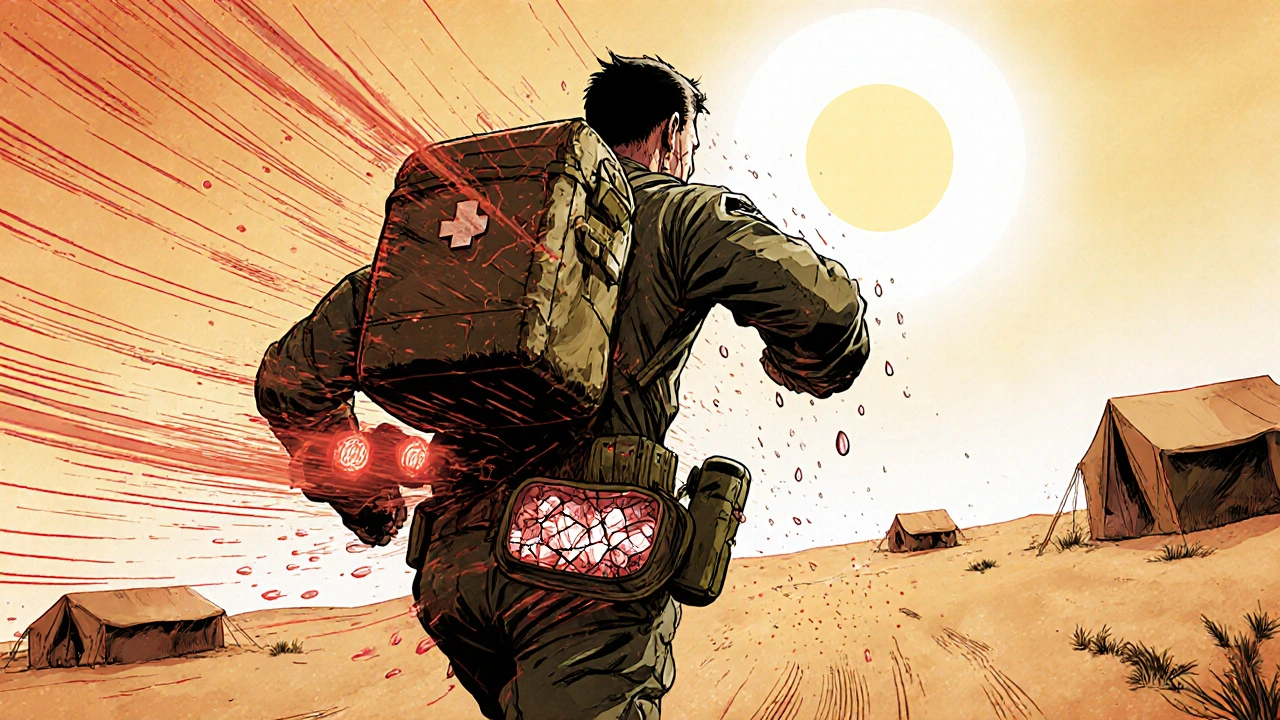

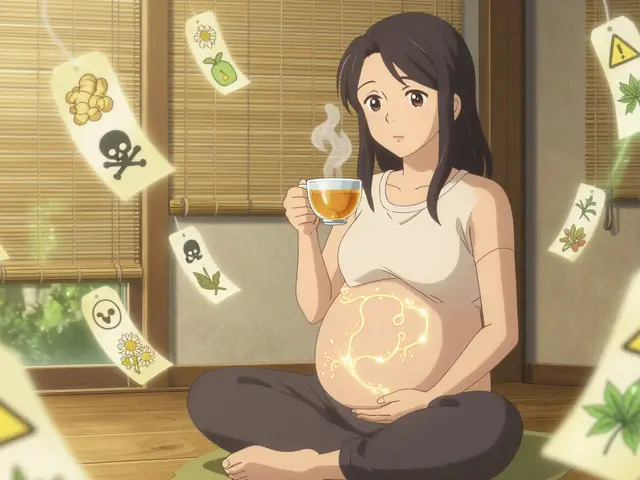

The military pharmaceutical logistics, the end-to-end process of moving medications from manufacturers to field clinics under strict environmental controls has to work in deserts, jungles, and Arctic fronts. That’s why specialized coolers, real-time temperature trackers, and hardened packaging are standard. The vaccine storage, the practice of maintaining vaccines within 2°C to 8°C from production to administration is especially critical—some vaccines, like the mRNA ones, require freezing at -70°C. The military uses portable ultra-low freezers, phase-change materials, and even solar-powered refrigeration units that run on battery or vehicle power. These aren’t lab gadgets—they’re field-tested gear carried by medics on foot patrols.

temperature-controlled transport, the movement of pharmaceuticals using insulated containers with monitoring devices that log every temperature change isn’t optional. In 2020, a U.S. Army field study found that 17% of vaccine shipments to remote outposts exceeded safe temperature limits—mostly because of delays at checkpoints or power failures during transport. Since then, every shipment now includes GPS-tracked loggers that alert command if the cold chain breaks. This isn’t just about compliance. It’s about trust. Soldiers need to know the medicine they’re given will work, no matter where they are.

And it’s not just vaccines. Antibiotics, insulin, epinephrine auto-injectors, and even pain meds like morphine rely on stable temperatures. Heat can cause pills to degrade into toxic byproducts. Freezing can ruin liquid formulations. The drug stability, how long a medication retains its potency and safety under specific environmental conditions is measured in hours, not days, when conditions are extreme. That’s why the military trains medics to check storage units before use, to recognize signs of spoilage, and to report anomalies immediately.

What you’ll find in the posts below isn’t theory—it’s real-world insight. From how field hospitals manage cold storage during power outages, to how drones are now being tested to deliver temperature-sensitive meds to isolated units, these articles cut through the noise. You’ll see how civilian cold chain tech is being adapted for combat, why some drugs fail in the field even when they’re FDA-approved, and what soldiers and medics actually do when the system breaks down. No fluff. No jargon. Just what works when lives depend on it.